Download ACE Press Release 12/2023

Download ACE Press Release 12/2023

Topic: ACE Safety Shock Absorbers Replace Rubber Buffers as Safety Elements in Film Industry

Ever faster tracking shots, ever higher resolution images: with the progress of digital film technology in the studios of production companies and broadcasters, the requirements for quality and safety of the equipment are increasing. One of the market leaders for cranes, dollies and tracking systems does not take any risks and relies on hydraulic safety shock absorbers as one part of their braking technology.

'Solid support on every set' is the promise of quality from Egripment, a globally operating company, specializing in the technical equipment of film and TV teams and corresponding services. The studio technology specialists from the Netherlands underpin the mixture of high-tech and after sales services with a lifetime guarantee on their dollies and cranes. It is therefore not surprising that Egripment's solutions can be found at many shows and events, at indoor as well as at outdoor sets. For example, the company supplies tracks for both ground and hanging constructions and corresponding remote-controlled dollies, which are essential parts of the program for film and television productions at open-air, hall and studio shows or concerts and also for sporting events, including Olympic Games.

The Fast and the Furious

In addition to quality and support, Egripment offers another big plus: engineering know-how that is based on more than 40 years of practical work in the Industry. It results from daily contacts with cameramen, crews, operators and technicians who are working at a continually higher professional level. In conjunction with their field experience, Egripment pays a lot of attention to design and innovation. Together with on-going consultation, the company ensures that way that the products suit the needs of all film markets. The result is the development of a sophisticated series of Egripment cranes, dollies, remote camera heads and different tracking systems.

Rick Velthof, Egripment's global sales manager, explains: "In addition to high quality, our customers expect a high level of reliability from our solutions, which we document, for example, with lifetime guarantees." He illustrates the requirements placed on Egripment's constructions with this comparison: "While it was still possible to end tracking shots with electronically controlled stops and to secure the remote-controlled camera dolly on the track system in the end positions using rubber buffers not too long ago, today's speeds in studios or at sports broadcasts are too high for this type of security element. Another case in point is the resolution that can be achieved, which is already 8K." High technical features such as these require current studio and recording technology to be calibrated very precisely before use and to maintain the same high level of data quality throughout the production. Rick Velthof: "Under these conditions, hardly any production can afford to spend a lot of time recalibrating a camera and dolly that have crashed into the rubber buffers due to incorrect operation or a sudden power failure and then bounced back. To get this duo back in line with the rest of the equipment such as control monitors and the lighting system can last up to three days in individual cases."

Such unacceptable downtimes in the visual area are one aspect for more security demands, the audible part of film technology is another one, since braking movements of many servo motors and especially of rubber buffers are anything but silent and can disturb the sound engineers during their work. The greatest concern, however, is preventing even more costly damage if the dolly and camera are seriously damaged in a crash at the end of the track. "Our Generic Track System is a remote-controlled camera system weighing up to 80 kg, which is moved on a track width of 40 cm at a maximum speed of 3 m/s over a maximum length of 50 m and also makes curves possible. If there is a real crash at the end of such a path, the damage to the camera alone can add up to over 100,000 euros," reports Rick Velthof. In order to avoid this type of accident on the set, the Egripment team took a close look at the market for safety products in the field of linear technology and became aware of ACE Stoßdämpfer GmbH from Langenfeld in Germany, a specialist in industrial damping technology. On one hand, Egripment’s attention was triggered by the online presence and the wide range of motion control solutions at www.acecontrols.co.uk as well as on the site www.ace-ace.nl/ in Dutch. On the other hand, it is also due to the personal presence of the ACE sales team in the Netherlands.

Last Man Standing

As a globally operating developer and supplier of industrial shock absorbers, ACE Controls Inc., founded 60 years ago near Detroit, Michigan, USA, is not only the inventor of adjustable shock absorbers and still the current technology leader, but also an enterprise which has been part of the Stabilus Group since 2016. ACE Stoßdämpfer GmbH, the German based subsidiary for Europe, covers the market with distributors and also with a team of sales engineers. In this particular case, as with many other applications before, Ralf Küppers and Han Titulaer, as representatives of ACE in the BeNeLux countries, were literally the closest. Rick Velthof from Egripment: "In addition to the good impression we already had judging by ACE's Dutch homepage, Ralf Küppers was quick to react and willing to visit us at short notice, thus taking in the construction on site and offering us a perfectly fitting hydraulic damping solution.”

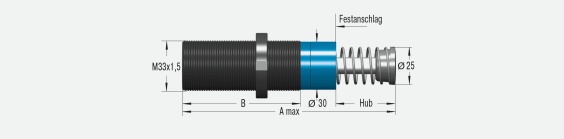

In Nederhorst den Berg in North Holland, which is in the immediate vicinity of Hilversum, internationally known for its television- and radio station, Ralf Küppers, thanks to the Egripment technicians, got to grips with their various track systems and dollies, as well as with the key data mentioned in terms of weight, speed and the route to be travelled on the track systems. "As a sports fan who had already seen modern remote-controlled cameras in use, for example in swimming competitions, I drove to Egripment with a rough idea of the performance of linear technology and the corresponding deceleration performance required. But in practice, in many TV stations, for example during game shows or live broadcasts with several fast-moving people or during concerts, the dollies reach speeds in excess of 50 km/h. This made me realize that in this case everything had to be smooth and noiseless in the event of an emergency stop – and also really fast." Accordingly, he used the design software from ACE, www.acecontrols.co.uk/uk/sizing/safety-products/online-calculation.html, entered the key data for mass, speed and distance and proposed the trial installation of two SCS33-25EU safety shock absorbers each at the end of the track construction erected for test purposes before. These hydraulic machine elements, which are designed purely for emergency stop tasks with a service life of up to 1,000 full load cycles, reliably provide their services in thousands of industrial applications, literally as the last man standing to protect linear constructions. They also serve as a kind of mechanical airbag for sensitive components such as sleds and the construction parts attached to them when they are accelerated on a track and, if worst comes to worst, need to be decelerated to 0 km/h immediately and without rebound effect, once hitting the end position. With laurels like these, Ralf Küppers felt confident that his company’s security forces that had already proven their qualities in countless emergencies and that are no strangers to gantries and conveyor systems, processing centers or assembly machines the world over, would also hold their ground when premiering in the film and television industry.

Silent Movie

Thanks to their compact design with a size of M33x1.5 and continuous threading, the security elements, each weighing 0.5 kg, can be quickly integrated into the construction and, with their dark, hardened steel outer bodies, look good in the anthracite-colored environment of film set devices. "In order to increase flexibility and adapt this emergency stop solution even better to customer-specific conditions on site, the SCS33-25EU dampers are mounted in universally adjustable clamping sleeves at Egripment. That way, they fulfill the function of stopping the dollies gently at the end of travel, and they also reduce damage and vibrations to a minimum. The specialty, however, about the universally adjustable clamping sleeves is that you can easily install intermediate stops when determining the track route and, in principle, infinitely long tracks can be secured," reports Ralf Küppers on the further course of the cooperation.

With a stroke of 23.2 mm, the self-adjusting safety dampers work with a regular energy absorption of up to 310 Nm per stroke in case of a dolly collision. This means that with the specified values of a maximum mass of 80 kg and a travel speed of 3 m/s in the event of an emergency stop, they consume 100 percent of the energy without rebound effects and emit the resulting heat to the environment via the steel outer body. Being more up-to-date for the requirements of modern film technology on the set thanks to the described main advantages for emergency stops, the hydraulic dampers offer another benefit over the previously used rubber buffers: They also exert less supporting forces on the tracks on impact, that is, when the accelerated masses hit the component. A bending of the track construction during the braking process was no longer found at Egripment after the installation of ACE’s solution.

The team around Rick Velthof has received good feedback from customers about the increased safety and additional possible uses of the hydraulic damping technology. It does not only show its strengths at full camera movement and maximum speeds of 0.5 m/s, but also convinces at the other end of the velocity range, in that the safety shock absorbers can be pushed through its stroke at a minimum of 0.02 m/s in creep speed. Under these conditions, the shock absorber provides minimal resistance to contacting masses, and there is no braking effect so that the team on the set can move the remotely operated dolly against the dampers almost in slow motion, ending the camera motion ultra-softly and very silently. With today's often automated technology and the high level of noise sensitivity in the studio, this is a further advantage compared to the dampers of the previous generation.

The Generic Track System is designed in such a way that the G-Track can be used as a base for many different applications and as the best base for fully computer controlled applications that allow control the dolly movements repeatedly and precisely, while it is also a perfect choice for fully automated applications. The G-Track system consists of a motorized dolly and can be configured with a telescopic column and a 2-axis camera head.

The Generic Track System is designed in such a way that the G-Track can be used as a base for many different applications and as the best base for fully computer controlled applications that allow control the dolly movements repeatedly and precisely, while it is also a perfect choice for fully automated applications. The G-Track system consists of a motorized dolly and can be configured with a telescopic column and a 2-axis camera head.

Egripment’s cranes, dollies and tracking systems are widely used in the film industry and now feature safety shock absorbers instead of buffers in end positions of tracks.

Egripment’s cranes, dollies and tracking systems are widely used in the film industry and now feature safety shock absorbers instead of buffers in end positions of tracks.

When using safety shock absorbers, the moving load, on impact, is smoothly stopped by a constant resisting force throughout the entire stroke. The moving load is decelerated with the lowest possible force in the shortest possible time, thus eliminating damaging force peaks and shock damage to machines and equipment.

When using safety shock absorbers, the moving load, on impact, is smoothly stopped by a constant resisting force throughout the entire stroke. The moving load is decelerated with the lowest possible force in the shortest possible time, thus eliminating damaging force peaks and shock damage to machines and equipment.

The slim-line, high-performance safety shock absorbers are designed for emergency stop situations only, while their compact design in sizes M33x1.5 to M64x2 makes their integration into a wide variety of current applications very easy.

The slim-line, high-performance safety shock absorbers are designed for emergency stop situations only, while their compact design in sizes M33x1.5 to M64x2 makes their integration into a wide variety of current applications very easy.